Keeping your lithium-ion battery safe and reliable is a significant benefit to its life cycle and performance. Your battery packs performance data can be analysed to record and action specific safety features such as a current surge.

Our BMS can also be configured to communicate data and indicate performance measurements through dedicated outputs or via CANbus/I2C/SMbus that can be easily accessed by the end user.

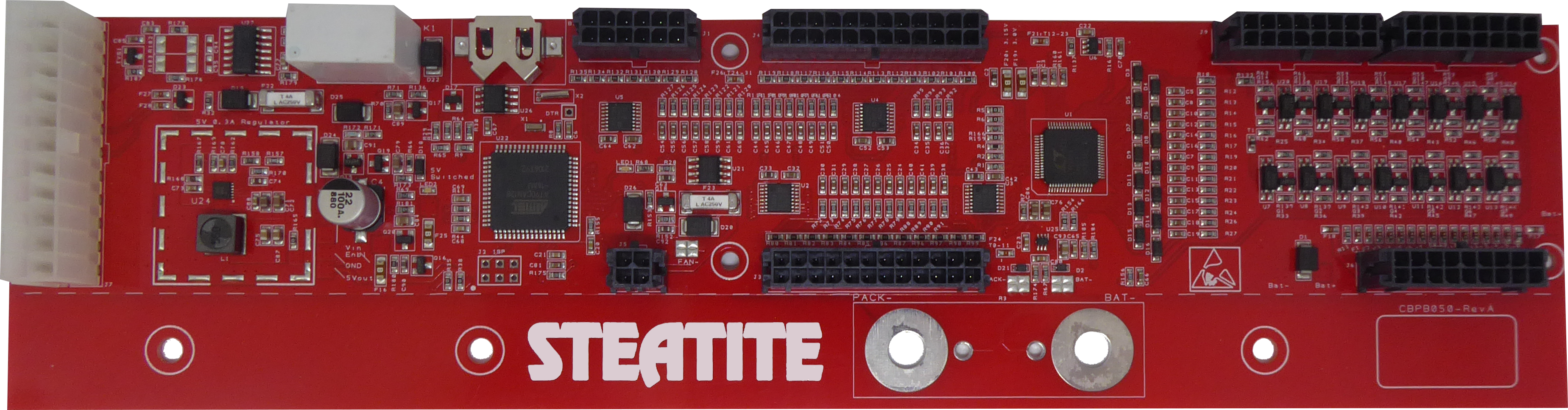

We have an existing range of BMS products that support small batteries comprising a few cells through to larger 48V+ large capacity products. The more complex BMS products can be programmed to suit your exact application.

Further our experienced team of electronics engineers and production operatives can design and test bespoke BMS should your application require it. We will integrate the battery management system within your bespoke lithium-ion battery pack.

You may have already identified some of the requirements your battery pack would need, or benefit from. Even if not, we can consult on your needs, providing an extensive list of safety, reliability, and output features for your consideration.

Our BMS products are designed to meet various international battery safety standards IEC62133 (Portable) / IEC62619 (Industrial) as applicable, as well as transport regulations (UN38.

Click on each of the elements to learn more.

| Feature | Definition/Benefit |

| Over Voltage Protection |

Definition – Monitors the voltage of each individual cell within the battery for rising above a set threshold, perhaps when charging. |

| Under Voltage Protection |

Definition – Monitors the voltage of each individual cell within the battery for dropping below a set threshold. |

| Over Current Protection |

Definition – Monitors the amount of current entering or leaving the battery pack. |

| Over Temperature Protection |

Definition – Temperature of the battery pack cells and circuit boards are monitored continuously for exceeding limits both hot and cold. |

| Balancing |

Definition – The BMS adjusts charge current flow to keep individual cells within the battery at very similar voltages. |

| Cloud Comms (optional) |

Definition – Upload diagnostic and performance data of the battery direct to the cloud. |

| I2C Comms |

Definition – Communication protocol between battery pack and the equipment – often used with smaller batteries. |

| CAN bus |

Definition– Communication protocol between battery pack and the equipment – better for larger products. Benefit – Allows the user equipment to access real time capacity, monitoring and performance of the battery pack. Sometimes used for linking multiple batteries together to form one large connected power source. |

| State of Health |

Definition – Access via I2C or CANBUS makes data available showing degradation level of overall battery. |

| State of Charge |

Definition – The capacity remaining within the battery pack. |