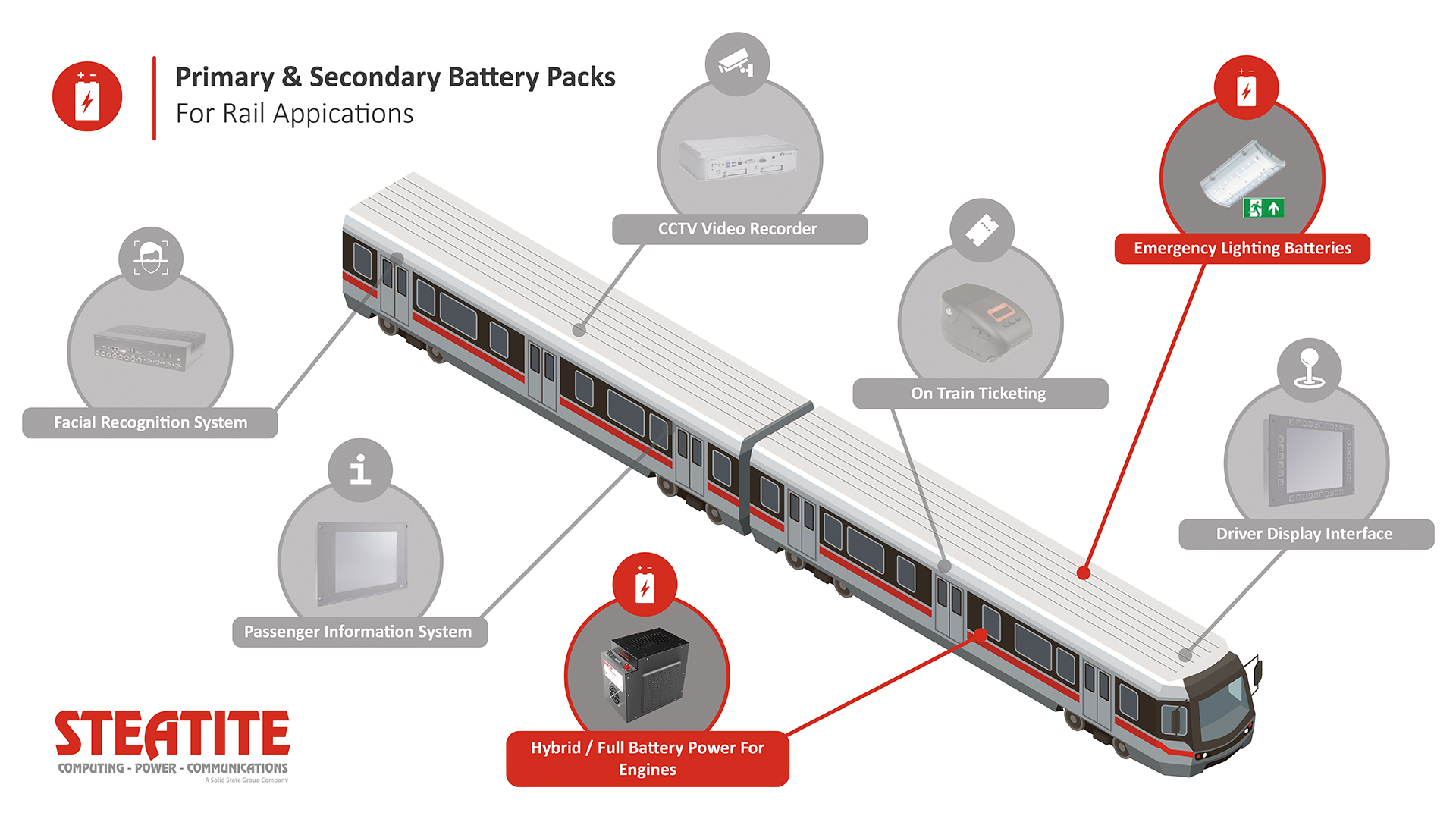

At Custom Power, we are able to design and build a wide range of battery packs for use in the rail sector. Whether powering specific on board systems or a full battery powered solution, such as a hybrid “last mile” concept, our batteries are meticulously designed and built to provide optimum power performance in the demanding environments experienced in on-board and rail side applications.

Major transportation businesses rely on Custom Power to provide the right battery or portable power solution based on specific application and environmental requirements. Our specialist battery packs are custom designed to deliver dependable power on demand, high reliability and peak performance in the harshest of environments.

Our partnerships with many of the world’s leading cell manufacturers means that we are well positioned to use the most suitable cells and cell chemistry for any given battery pack application.

In addition to our bespoke battery packs, our modular based system allows great versatility by linking together in a combination of series and/or parallel to meet individual requirements based on voltage and capacity, as well as safety, cycle life and cost.

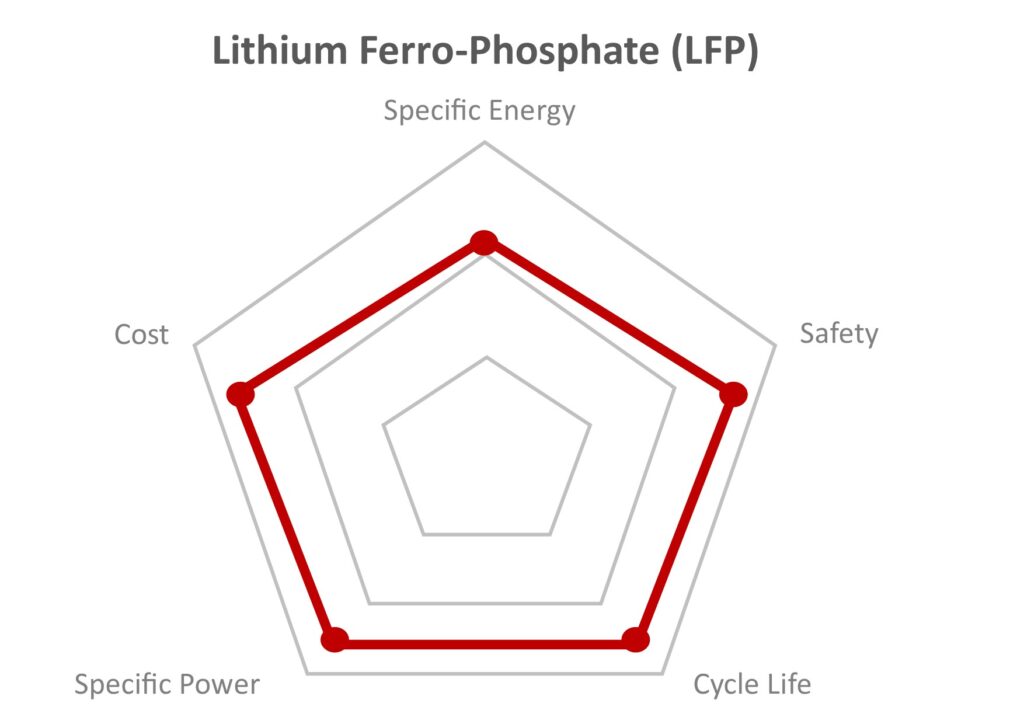

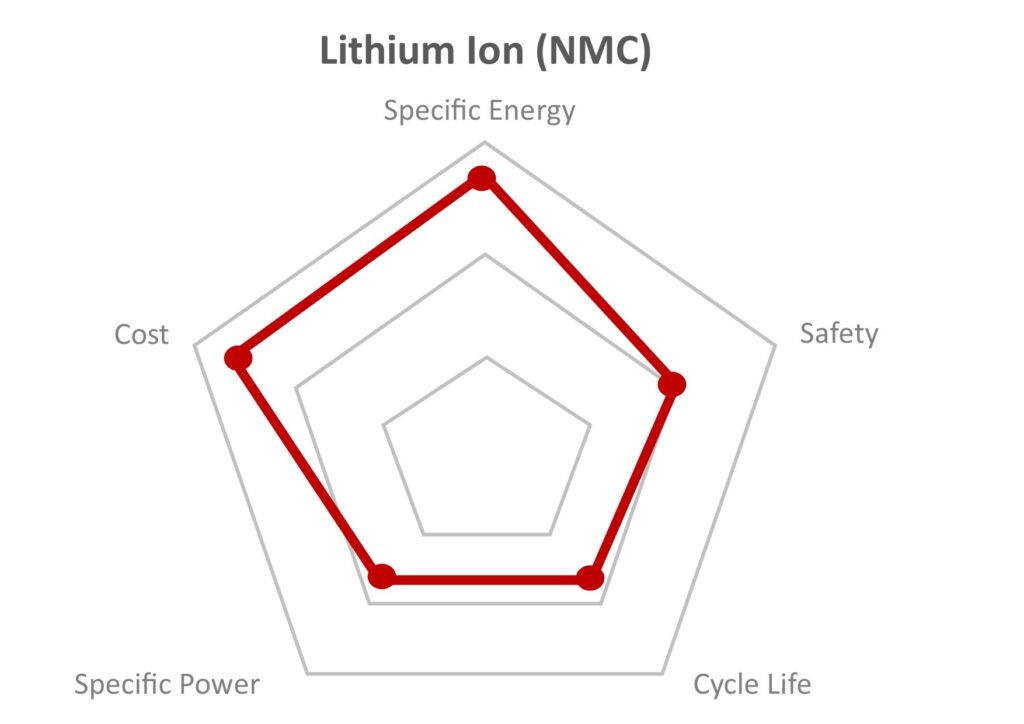

Most common cell options for battery packs used in the rail sector are lithium-ion (NMC) and lithium ferro-phosphate (LFP). Which of these is used for a particular battery pack depends on the required parameters as both offer differing characteristics.

For certain applications, LFP has a number of key advantages; unbeatable cycle life, power capability and safety. Li-ion excels in applications where cost and specific energy (greater energy for a given volume or weight) are of more importance. For small applications where the highest energy density is critical (e.g., mobile phones) li-ion is the right solution. Where space is less at a premium, the advantages of LFP very quickly outweigh the li-ion chemistry.

Custom Power battery packs combined with our own in-house battery management system (BMS) enables constant monitoring of each aspect of the battery pack and individual cells to give the end-user a picture of all key elements of the pack’s performance.

During the design and production process, we utilise Prince2 (PRojects IN Controlled Environments) methodology ensuring key milestones are delivered from pre-design review to full factory acceptance.

Custom Power modular battery packs are meticulously designed for reliable continuous daily usage in harsh environments where shock, vibration, and varying temperatures are likely to be experienced.

Produced in a range of chemistries such as NiMH, NiCd, Lead Acid.