Designing and manufacturing superior custom batteries

Steatite has extensive experience of manufacturing custom battery packs and we’ve just added extra capability to our remit.

Our engineers have been successfully spot welding and arc welding packs for a number of years. Spot welding is suitable for the vast majority of our cells, where parts are up to 3mm in thickness. The process does not require excessive heat and the energy delivered to the spot can be carefully controlled to produce reliable welds. Our semi-automated production lines are tailored specifically to create the optimum bond for specific cells and applications, and regularly adapted for changing requirements.

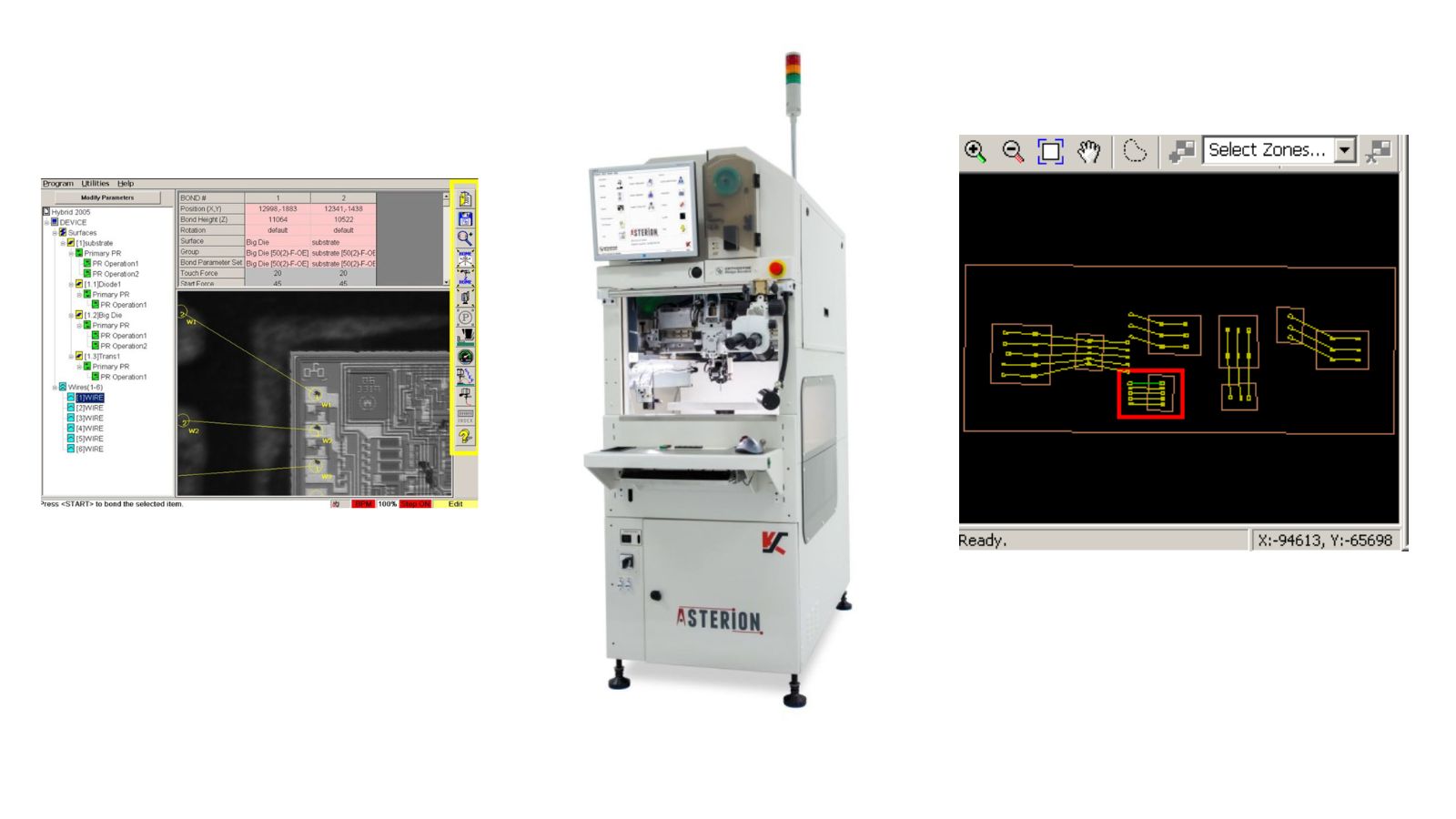

We’ve recently installed an Asterion™ wire bonder, manufactured by K&S and provided by Inseto to add wire bonding to our inhouse capabilities.

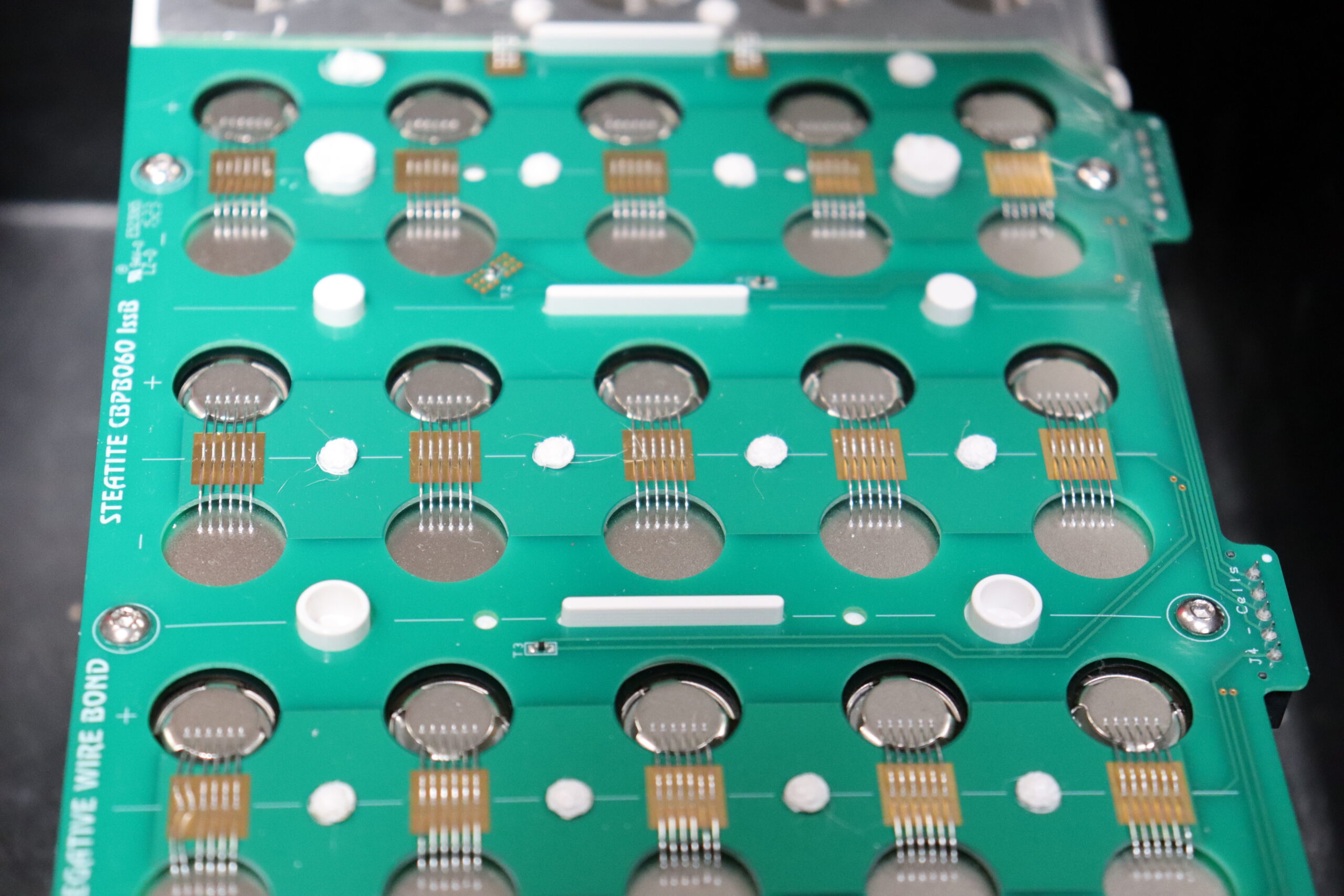

Compared to traditional methods of interconnecting, wire bonding enables manufacturers to offer custom battery packs with high discharge capabilities and reduced assembly time (in a shorter lead time) which meet even higher levels of reliability and safety. Wire bonding helps to prolong cell life and improve battery performance as a result of lower resistance.

Steatite specialises in creating custom batteries which often need to be built in a particular size and shape for unusual housings, and wire bonding allows us the flexibility to place cells in tailored positions and still maintain strong and dependable connections.